Brice Robbie Derek

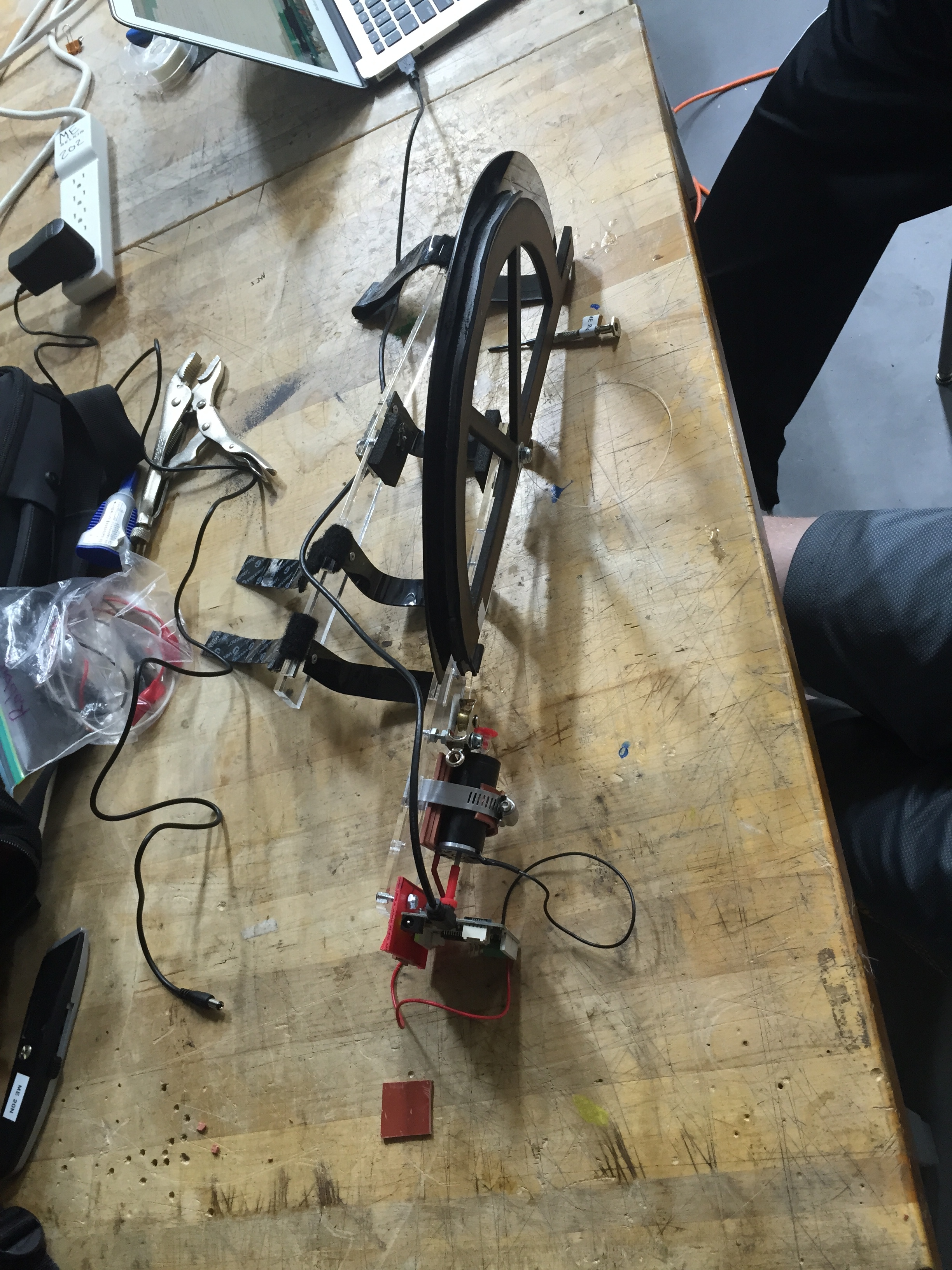

Finished Haptic Bicep Curl prototype

ready for presentation .

The Haptic Bicep Curl

Project team member(s): Derek Phillips, Brice Dudley, Robbie Hewitt

The original goal of the project was to create a device that could remove the danger and uncertainty from weightlifting. The device would accomplish this in two ways: it would be wearable, thus it would be difficult for the user to drop on his/herself; and it would apply a force in a very specific way that was predetermined by the mechanical design (only having one point of contact), and in the process limit the ability of the user to use improper lifting techniques. However, it proved beyond the scope of our resources to provide a large enough force to constitute weight lifting, thus the aim of the project changed slightly. The device we created as a proof of concept, proving that it is possible to create a wearable device that can exert a force in a predetermined way onto the user. We successfully created a wearable device that applied a specifically calculated force in the intended way on the user. With further research, the project can be scaled with better motors/design to create a much more significant force, and eventually could be expanded to have alternate product lines for other muscle groups.

Introduction

As soon as we heard about the project, we immediately decided that we wanted to create a haptic device that could improve upon some aspect of our lives. We began thinking of places in our lives where we use technologically simple devices that can have a negative impact on our lives (i.e. being dangerous or difficult to use correctly). The weight room sprang to mind, and with it came the idea of "wearable weights". The Haptic Bicep Curl is a device that would remove the danger from free-weight lifting and make it easier for the user to correctly target the intended muscle groups. Since it is wearable, the user would not be able to drop the device and injure themselves. The device would also apply force independent of where the user's shoulder was, thereby preventing improper lifting technique.

Background

The Haptic Bicep Curl was designed to remove the dangers out of weightlifting such as dropping weights and exercising incorrectly. Although this idea was not researched prior to our starting the project, it was not a new concept. Examples of this technology are the FlexTorque and FlexTensor (http://www.researchgate.net/publication/220947235_ExoInterfaces_novel_exosceleton_haptic_interfaces_for_virtual_reality_augmented_sport_and_rehabilitation). As far as the code goes, it did not have to be altered from the original Hapkit code (http://hapkit.stanford.edu/files/HapkitLab4SolutionsForWebsite.ino) too much. The main difference between our code and the Hapkit code is the formula used. In our code, the force equals mass times gravitational acceleration was used.

Design

Hardware design

The basic premise of our design was based off the idea of an elbow brace. We considered many different designs, ranging from devices that enclosed the whole arm to ones that were attached by nothing but Velcro. We finally settled on a mixture of the two. Our Haptic Bicep Curl was designed to optimize two critical components of anything wearable— rigidity and weight. The Haptic Bicep Curl had to be strong enough to withstand the inherent forces of the assembly, while at the same time being lightweight enough to wear around.

The Haptic Bicep Curl is comprised of four main sections: the sector (lower outside), the upper outside, the inner lower arm, and the inner upper arm (see illustrator files for ready-to-print parts). All orientations are in regards to the right arm. The largest piece of the Haptic Bicep Curl is the semicircle sector made of ¼ inch Duron which serves to effectively amplify the torque from the motor (see the equation in the code). Attached to this was the upper outside piece of acrylic which, like the remaining two pieces, was cut from ¼ inch acrylic. This upper sector piece was flared from one inch to two inches towards the top to provide room for mounting the motor. Both pieces were attached using a 3/8 inch bolt and four washers to reduce friction. The inside arm side of the brace was composed of two strips of acrylic that were one inch wide. Again, they were connected with 4 washers and a 3/8 inch bolt. When attaching the upper and lower sides of each side of the brace, it was important to attach them so that the lower sides were on the outside of the upper sides. This was due to the fact that the lower arm is wider than the upper arm. Within both sides of the brace, a series of four 1/8 inch holes were cut, two on the lower potions of each side and two on the upper portion of each side, so that they corresponded in position to the hole on the opposite side. Likewise, three slits were cut, two on the upper portion and one at the end of the lower portion on both sides of the brace, so that they too were corresponding in position to the slit on the opposite side. The one slit on the lower portion was located at the radius because we wanted the Velcro to apply the Haptic Bicep Curl's torque, while the two slits on the upper part were just for stabilization Velcro. Two other slits were cut an inch apart on the two inch wide section of the upper outside of the brace to be used to mount the motor. These two sides were then connected by 1/8 inch flexible acrylic which was cut into 7x1 inch strips with 1/8 inch holes at each end of the strips and molded to fit the contours of the arm. Rivets were used in connecting the thin acrylic to the inside of each side of the brace through the 1/8 inch holes on the brace and the acrylic. In the three slits that were cut on the inside side of the brace, Velcro was fed through and attached so, it could then be pulled over the users arm, though the slit on the other side, and then back on top of the arm to lock it into place. An 1/8 inch thick piece of acrylic was then cut with a slightly larger radius than the sector and attached to the inside of the sector to serve as a guide for the string along the sector. The Maxon motor was then attached using a hose clamp wrapped through the holes in the upper outside acrylic piece. It was placed on the top of a spare ¼ inch piece of acrylic and wrapped in rubber for protection. A spool was then designed using Solidworks (see attached file) to attach the string to the motor shaft. On the motor shaft facing backwards a Hapkit motor pulley with magnet was attached. The Arduino was then attached to the upper outside piece so that the magnet aligned with the MR sensor integrated into the Arduino allowing position data to be recorded which then enables the force compensation as a function of the angle of the arm (change in gravity.) The final aspect of the system to be attached was the pulley. It was attached just below the spool on the motor and orientated so the string was perpendicular to the spool. The string was then attached to the spool (through a tiny hole), wound around the pulley, and attached to the sector through the pivot point.

Software design

The Haptic Bicep Curl had two different codes. The first code, adjusted the force due to the angle of the arm in order to simulate gravity. This would give the user a more realistic experience while using the machine. In order to make sure the maximum force was at one hundred eighty degrees, the mass was calculated beforehand and later applied to the formula in the code. The second code applied a constant force on the user instead of adjusting it due to the angle of the arm. This code was mainly used to make sure the device worked as expected and as a backup incase the gravity code didn't go as planned. Once the force was calculated, the torque of the motor was found by using an equation derived using the measurements of the device [Torque of the motor = (force * radius of the motor pulley * radius of the arm) / radius of the sector pulley].

Functionality

The Haptic Bicep Curl does exactly what the name implies: it simulates the torque applied when doing a bicep curl with a physical mass. To use the Haptic Bicep Curl, the user simply places their right arm inside of the brace, securing their arm with three strips of Velcro. During the haptics open house our group was approached by a graduate student who was taking on a project similar to ours. However, instead of creating a haptic device for the whole arm, the student was concentrating on a haptic exercise of sorts for just the wrist. The student was very impressed that we had built such a device and pondered our design in regards to ideas for their device.

Originally we had hoped to mimic a range of weights anywhere from one to ten pounds. However it was quickly realized that no motor existed within a reasonable price range that had enough torque to meet these demands. In opting to use a cheaper Maxon motor ($300 - which Allison was kind enough to loan us) we were able to generate roughly the lower end of our weight spectrum—one pound. In regards to this new, reduced maximum weight, the Haptic Bicep Curl served both as a proof-of-concept and as a rebranded Haptic Rehabilitation Device for those who, due to injury, cannot handle much weight. The system could be improved first and foremost by upgrading to a higher torque motor or multiple motors. Additionally, the pulley used for redirection of the string could have been of a higher quality, thus ensuring the string would not slip off. Finally, the flexible acrylic strips that connected the bottom of the two sides of the brace together could have been molded more ergonomically, making it easier for the device to be worn.

Getting Swol: The Haptic Bicep Curl in Action

Acknowledgments

We would like to convey our utmost thanks and appreciation to all the wonderful PRL TA's, Allison Okamura, and Jeanny Wang for their help in various aspects of the design. Without your combined guidance the successful completion of this project would have been impossible.

Files

The file of the majority of the design portion. Each individual section was copied from this document to be printed.

This is the file we used to cut the guide to keep the string on the sector pulley (semi circle).

This file was used to cut the pieces of acrylic that serve as the underarm bands to keep the device intact.

This is the code that adjusts the force due to the angle of the arm, simulating gravity.

This is the code that applies a constant force to the user.

This is the Solidworks file for the spool.